3 in 1 Funtions

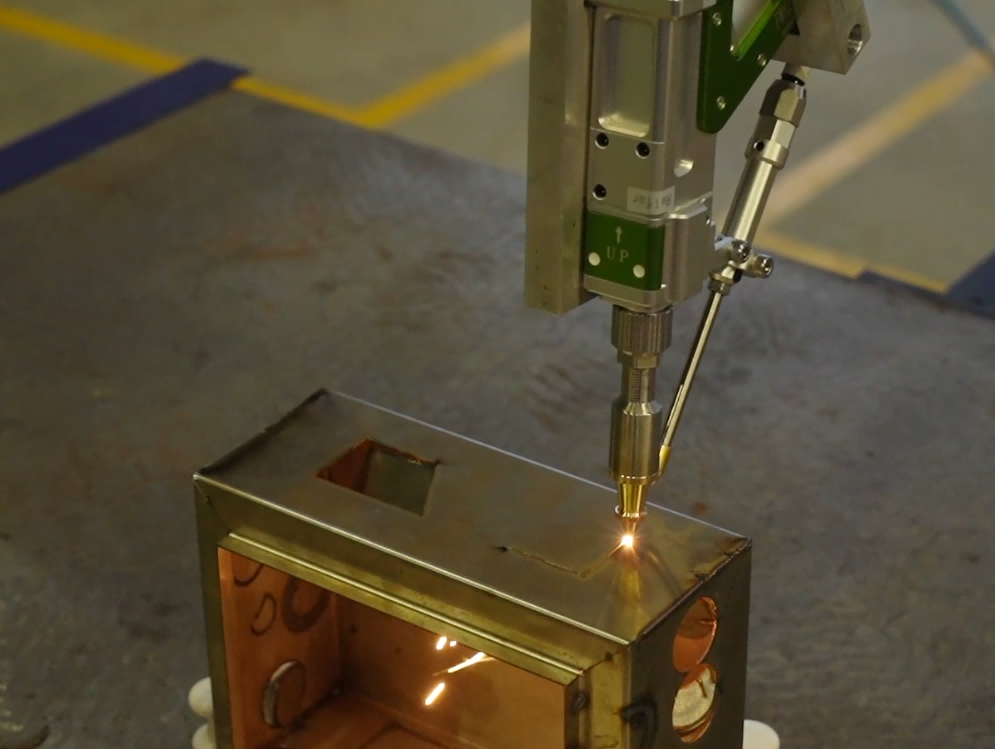

Welding Function

The laser welding machine has fast welding speed and improves welding efficiency. Good welding effect, improve the yield rate. Easy to operate, inexperienced people can quickly learn how to operate the equipment within 5 minutes, saving labor costs for factories.

Cutting Function

Change the parameters in the control panel, and choose the nozzles for cutting, the machine can be switched to the cutting mode. It is able to cut thin metal sheets easily and quickly, speeding up factory production efficiency.

Cleaning Function

The cleaning function is available by replacing the front of the laser head and switching the control panel to cleaning mode. Laser cleaning can quickly remove rust from metal surfaces, and factories that process carbon steel will often use this function.

Collaborative Robot

| Robot Mode Option | i5 | i10 (standard) | i16 |

| Loading Weight | 5kg | 10kg | 16kg |

| Robot Weight | 24kg | 38.5kg | 38kg |

| Repeat Accuracy | ±0.02mm | ±0.03mm | ±0.03mm |

| Working Radius | 886.5mm | 1350mm | 967.5mm |

| Collaborative Robot VS Traditional Robot Arm | |||

| Safety | Work with Person | Work only in fences | |

| Usage | Hand simple programming | 3D modeling software programming | |

| Flexibility | Lightweight, mobile, easy to install, plug and play | Poorly adapted to the environment | |

| Applications | Industry and home using | Only industry using | |

Laser System

Laser Source

Professional welding laser source, small in size, light in weight, and easy to move. The light emitting mode is more conducive to achieving a good welding effect. Support laser powers from 1kw to 3kw.

Water Chiiler

When using an industrial chiller, pure water is used in summer, and antifreeze is used in the water when the room temperature is below 5 degrees Celsius . Switch back to pure water when the temperature warms up.

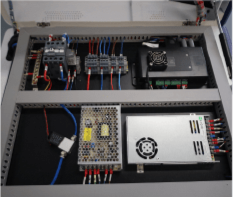

Control Cabinet

With neat control cabinet internal wiring, International top-brand electrical components and pneumatic components. At the same time, given our customers best user experience for a long warranty period.

Laser Welding Head

Laser Head

The laser generated by the laser source is transported to the welding head, then is collected and reflected by a reflector and focused by the focusing lens to reach the nozzles and finally fired to the materials.

Nozzle

Different shapes of nozzles are suitable for different jobs. It need chooses the right wire material when used with a wire feeder. When switching to cutting mode, a special nozzle for cutting is required.

Lens

There are Protective Lens, Focal Lens and Reflective Lens inside the Laser Head. Normally, Protective Lens are the wearing parts, when working after a long time, the user may need to change new lens to continue to work.

Control System

Control Switch

Simplified switch system, only one power switch, saving the operator's time. The emergency stop switch protects the operator and quickly stops the equipment from working.

Control Panel

Touch screen makes you change the parameters quickly when wearing gloves. Multiple sets of parameter can be saved, and there is no need to adjust again for multiple welding times in the future after one test.

Wire feeder

With Standard automatic wire feeding system and dual motors, The forward and reverse and the speed of wire feeding can be adjusted through the control panel.

Note: Standard is Single Feeder

Product Paramenters

| Wire feeder | LW-R-3 Collaborative Robot Welding Machine |

| with 3 in 1 Laser Function | |

| Laser Power | 1000w (Option: 1500w, 2000w, 3000w) |

| Laser Fiber Wire Length | 10 m |

| Laser Output power adjustment range | 10%-100% |

| Laser Source | MAX (Option: Raycus, IPG, BWT, Reci) |

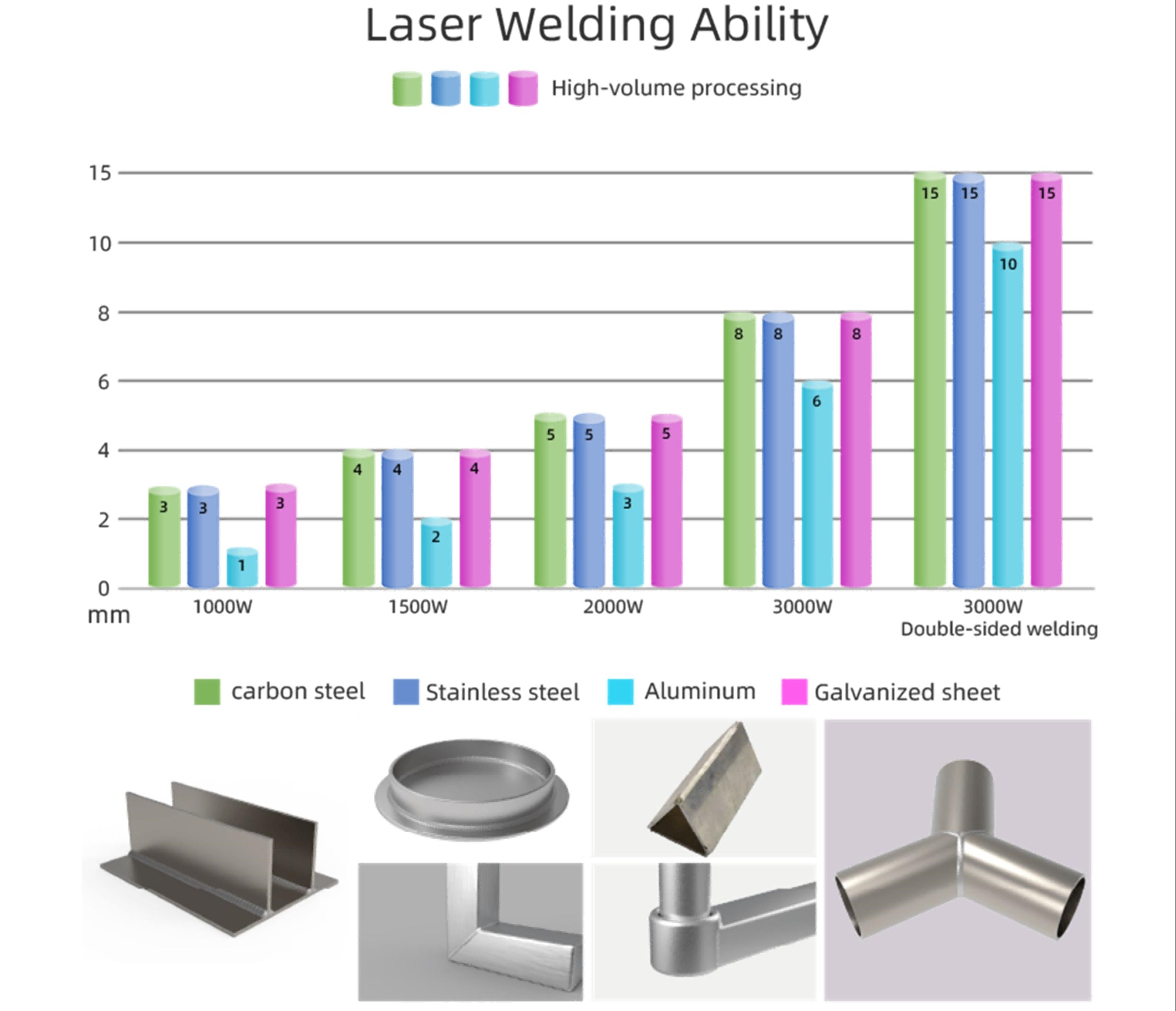

| 1000w Welding Ability | Stainless steel 3mm, carbon steel 3mm, galvanized plate 3mm, aluminum plate 1mm |

| Control System | Raytools (Option: Relfar, Gefasst) |

| Control Panel | Touch Screen 7 inch |

| Support Languages | 18: Chinese Simplified, Chinese Traditional, English, Polish, Turkish, Arabic, Japanese, Korean, German, |

| Spanish, Russian, French, Portuguese, Italian, Hungarian, Czech, Finnish, Vietnamese | |

| Auto Wire Feeder | Single Type, Load Weight 20KG |

| Cooling Method | Water Cooling |

| Auxiliary Gas | Nitrogen or Argon gas |

| Note: Cleaning mode can use compressed air | |

| Voltage | 380V 3PH 50HZ/60HZ (Option: 440V) |

| Package Dimension | 1460*1260*860mm (Table and Robot) 160*960*1360mm (Welding Machine) |

| Package Weight | Total 1050KG (800kg and 250kg) |

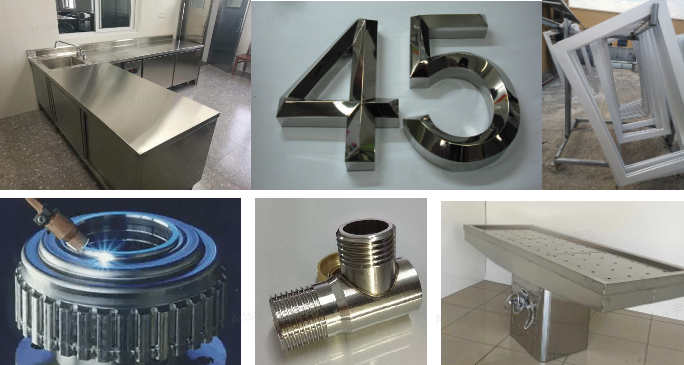

Application & Samples

Application Industry

Kitchen and bathroom industry, advertising industry, door and window industry, mold industry, stainless steel Products industry, handicraft industry, furniture industry, home appliance industry, auto parts industry, etc.

Welding Sample & Ability

Product Shipment

| Shipment Method | Sea freight, Land freight, Air freight etc. |

| The total weight and dimension is too big, not recommend to use express as the shipment method. | |

| Package Method | Wooden Case |

| Noted | If you need to ship by air, please let us know before purchase, and you need to empty the gas in the water cooler before shipment. |

| And there have the motor inside the machine, therefore if use the Air shipment, it has to make the "Electromagnetic inspection", which cost around 80USD per time. |