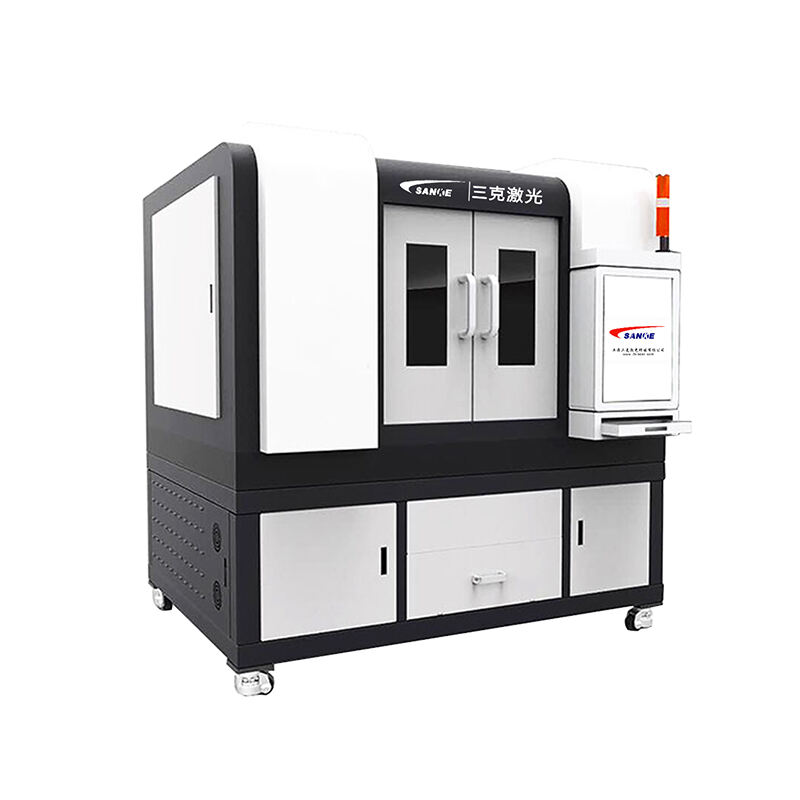

hans laser cutting machine

The Hans laser cutting machine represents a pinnacle of precision engineering and advanced manufacturing technology, designed to meet the demanding requirements of modern industrial applications. This sophisticated equipment combines cutting-edge laser technology with robust mechanical construction to deliver exceptional performance across various materials and thicknesses. The Hans laser cutting machine utilizes high-powered fiber laser sources that generate concentrated light beams capable of achieving remarkable cutting speeds while maintaining extraordinary accuracy levels. The machine's core functionality revolves around computer-controlled positioning systems that guide the laser beam with microscopic precision, enabling operators to execute complex cutting patterns and intricate designs with consistent repeatability. Advanced motion control algorithms ensure smooth acceleration and deceleration, minimizing vibration and maximizing cutting quality. The Hans laser cutting machine incorporates intelligent height sensing technology that automatically adjusts the focal distance based on material thickness variations, ensuring optimal cutting performance throughout the entire operation. Temperature monitoring systems continuously track thermal conditions, preventing overheating and maintaining stable operating parameters. The machine features comprehensive safety protocols including protective enclosures, emergency stop mechanisms, and laser radiation containment systems that comply with international safety standards. User-friendly interface design simplifies operation while providing extensive customization options for different cutting requirements. The Hans laser cutting machine supports various file formats and integrates seamlessly with popular CAD software packages, streamlining the workflow from design to finished product. Maintenance requirements are minimal due to the robust construction and high-quality components used throughout the system. Regular calibration procedures ensure long-term accuracy and reliability, making the Hans laser cutting machine an excellent investment for businesses seeking dependable manufacturing solutions.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES