Introduction

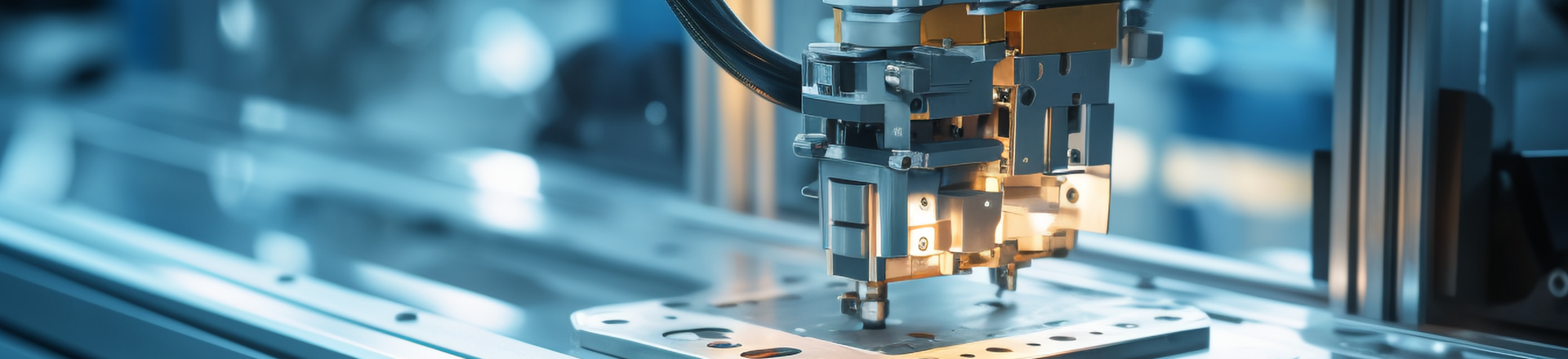

The following features make laser drilling one of the precision and versatility parts that help it to become one of the indispensable within the manufacturing industry. A Laser Drilling Machine employs a narrow laser beam to drill relatively small holes into different types of materials. Contents What Materials Can Laser Drilling Machines Laser Drill Machine Advantages And Drawbacks In Different Industries

Advantages of Laser Drilling

Specifically drilling well about laser when contrasted with driven penetrating techniques has preferences. Since the entire process is done non-contact, tool wear has been reported to be very, very low, thus leading to better tool life and less downtime. Laser Drilling also provides Holes that are factual & near-spec that is less drift from the target specs due to high precision & accuracy. In comparison, its heat-affected zone is small, thus the distortion loss of the material is small and the work piece is not damaged.

Laser Drilling Able Materials

Photo: Getty Images Laser drilling machines work with several materials such as:

Metals (stainless steel, aluminum, titanium, copper, and their alloys) are the most common material that lasers are used to drill. Laser drilling has the ability to penetrate these metals with precision and in a clean manner: laser beams are high energy and easily guided.

B) CERAMICS - We all know that laser drilling of industrial technical and advanced ceramics can be carried out. In such cases where these hard, brittle materials are drilled, the benefit here is the ability to drill without fracturing using laser drilling methods.

C. Plastics and polymers: Laser drilling of plastics such as acrylic, polyethylene, PVC and PTFE is burr-free and no burr hold with no heat-affected zone shall be provided with advantages of no melting or distortion.

D. compositesThe CFRP and GFRP are also important materials, categorized as composites, and their properties are more complex which where more laser-drilled and only through them can further complex or higher-cost materials be used with higher accuraccies with the least damage to kerf [23].

The two largest materials in the electronics industry — silicon, and gallium arsenic — can be laser drilled like we have done in our study.

F: Glass and quartz—potash-lime glass, borosilicate glass and fused quartz are excellent candidates for laser-drilling with a clean hole at the exit as well as maintaining the stability of their thermal damage threshold.

Material Laser Drilling Measures

Material properties (thermal conductivity, absorption coefficient, etc.), laser parameters (wavelength, power and pulse duration), drilling geometry and hole characteristics all play important roles in whether a laser drilling process will succeed or fail. So these factors are of utmost importance for controlling the laser drilling process.

Limitations and Challenges

Despite the advantages, laser drilling, as with all technologies, has limits. Certain highly opaque and reflective materials, such as metals, reflect rather than absorb and these too can be thus be difficult to drill. Furthermore, carbon-based nanomaterials are usually thermally insulative, which limits the generated heat to much extent. Or otherwise the hardness-Zone of some materials forms diffraction high tolerance holes as occurrence of cracking and/or fracturing.

Use of laser drilling across different domains

These laser drilling machines give repeatable precision holes, which is the reason it is utilized in different ventures. Within the aerospace industry, those are what drill holes in parts and systems. For instance, laser drilling of fuel injector nozzles and other automotive components In electronics, laser drilling is a part of PCB and MEMS fabrication. Laser drilling is a good process in the medical industry to manufacture precision instruments and implants. Finally, the energy industry uses laser drilling for the manufacture of solar cells and fuel cells.

Conclusion

In this publication, versatile laser drilling machines show that they offer high precision and high efficiency with proven results in a wide material spectrum. Laser drilling is a high throughput process that is highly dependent on the material and laser parameters used. This is a landmark step for laser drilling, and in this material compatibility, and we might see more technology developments into the other materials with larger developments in production in the near future.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES