Introduction

Handheld laser cleaning machines represent a breakthrough in surface treatment processes for various Applications in different industries. In addition, these devices are Precision and effective due to an alternative to manual methods of cleaning, descaling, and removal of paint or contaminants; where they remove contaminants, rusts and coatings and do this safely while not destroying the underlying materials. But, but whether or not these machines are effective all comes down to how precise they can get and the safety precautions during use. In this article, we consider the example of manual laser cleaning machines and how these ensure a high level of precision & safety during the cleaning process.

Precision in Laser Cleaning

Laser beam delivery has advanced so much that it is now highly controlled for precision in laser cleaning. High-brightness, well-collimated CW or pulsed laser beams are delivered via handheld devices to targeted surfaces. Pollutants absorb the energy and undergo physical or chemical transformation like vibration, melting, vaporization leads—to removal of contaminants without damage to substrate. Configurable focusing and forming of the laser beam via optical elements enable accurate addressing of the contamination paint layer that provides fine surface finishing to be able to move on to other industrial processes.

Power density and pulse width are key variables to be controlled in order to reach the desired cleaning effect. The power density has to be high enough to achieve efficient cleaning, but not so high as to damage the substrate. The materials have a thermal impact so the shorter pulses are always better because it more or less minimizes heat. Further, the speed of scanning and defocusing methods are tuned to provide efficiencies in cleaning with respect to damage threshold. Further unfocused expands the area of high flux around the focal point with larger spot sizes and greater scanning areas allowing for increased productivity without sacrificing cleaning efficiency.

Safety precautions in laser cleaning

Safety should be at the forefront of things to consider when using handheld laser cleaning machines. Operators are required to put on Laser Safety Glasses; which guard against eye injury from laser radiation and a cutting edge dress, if relevant as protection against reflected beams.

Effective ventilation and exhaust systems are important in cleaning to control the release of hazardous chemicals into the air. These systems reduce the dispersal of harmful gases and particulates, making for healthier conditions that protect the operator.

High-energy laser beams can also set flame to combustible materials, so fire safety precautions are crucial. Equipment to fight fires and an emergency evacuation plan will have put in place to deal with possible fire hazards.

Electrical safety is also important, particularly as high-voltage equipment used in laser cleaning machines poses an additional threat. Inspections should be made and measures to ground the conductor kept proper so as to prevent electric shock.

Top Tips For Good Operator Training and Equipment Maintenance

Operators need to be trained in a professional way of how the machine works and safety standards. Routine maintenance and periodic inspection of equipment assures that the cables, as well as connections are fine and hold things together without any dislocation which may lead to safety concerns.

Laser safety requirements require that you follow the guidelines recommended in ISO etc. They offer guidance about minimizing risks created by particular hazardous scenarios and that operators should be able to find effective methods for controlling materials properly along with protective measures.

High-End Precision and Safety

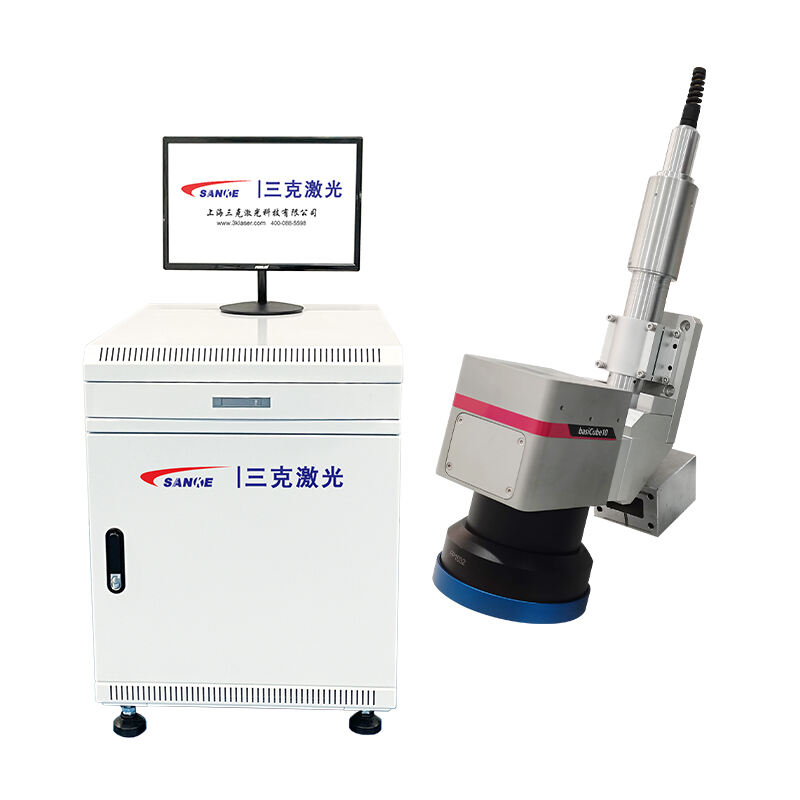

Today, new laser cleaning machines for handheld devices provide advanced features, boosting the accuracy and being equally concerned about user safety. PX-Mod Easy is easy to use, and a portable and lightweight construction which allows the operator to execute laser settings with precision at their display using touchscreen controls.

Water cooling systems guarantee strong performance for high-power applications, capable of providing coolness against overheating and keeping the machine working stable and safe.

Conclusion

Handheld laser cleans are an accurate and safe alternative for traditional cleaning along with the advance technology, like operator training & implementation of safety protocols to guarantee a secure and effective process. These will only increase as technology advances, thereby increasing the precision with better safety in many different applications. So far, the perfect technical performance and safe operation make manual laser cleaning machines become an indispensable tool in modern industrial processing.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES