Laser Drilling

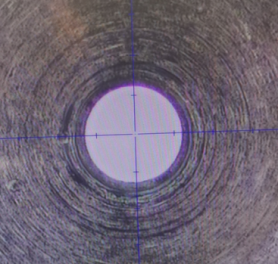

Laser Drilling represents a revolutionary advancement in precision manufacturing technology that utilizes focused laser beams to create holes in various materials with unprecedented accuracy and speed. This cutting-edge process employs high-intensity laser light to vaporize or melt material, forming precise holes without physical contact between the tool and workpiece. The Laser Drilling system operates through sophisticated beam control mechanisms that direct concentrated energy to specific points, enabling manufacturers to achieve hole diameters ranging from micrometers to several millimeters. The technology incorporates advanced optical systems, computer-controlled positioning mechanisms, and real-time monitoring capabilities to ensure consistent results across diverse material types. Modern Laser Drilling equipment features programmable parameters including pulse duration, frequency, power levels, and beam focus characteristics, allowing operators to customize the drilling process for specific applications. The system's primary functions encompass creating cooling holes in turbine blades, producing micro-vias in electronic circuits, forming injection holes in fuel systems, and generating precise apertures in medical devices. Technological features include multi-axis positioning systems, automated material handling, integrated quality control sensors, and user-friendly interface software. The process excels in materials such as metals, ceramics, polymers, composites, and semiconductor substrates. Applications span aerospace manufacturing, electronics production, automotive component fabrication, medical device creation, and energy sector components. The Laser Drilling method delivers exceptional repeatability, minimal heat-affected zones, and the ability to process materials that traditional drilling methods cannot effectively handle. This technology enables manufacturers to achieve tight tolerances while maintaining high production rates, making it indispensable for industries requiring precision hole formation in complex geometries and challenging materials.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES