Versatile Material Processing Capabilities Across Industries

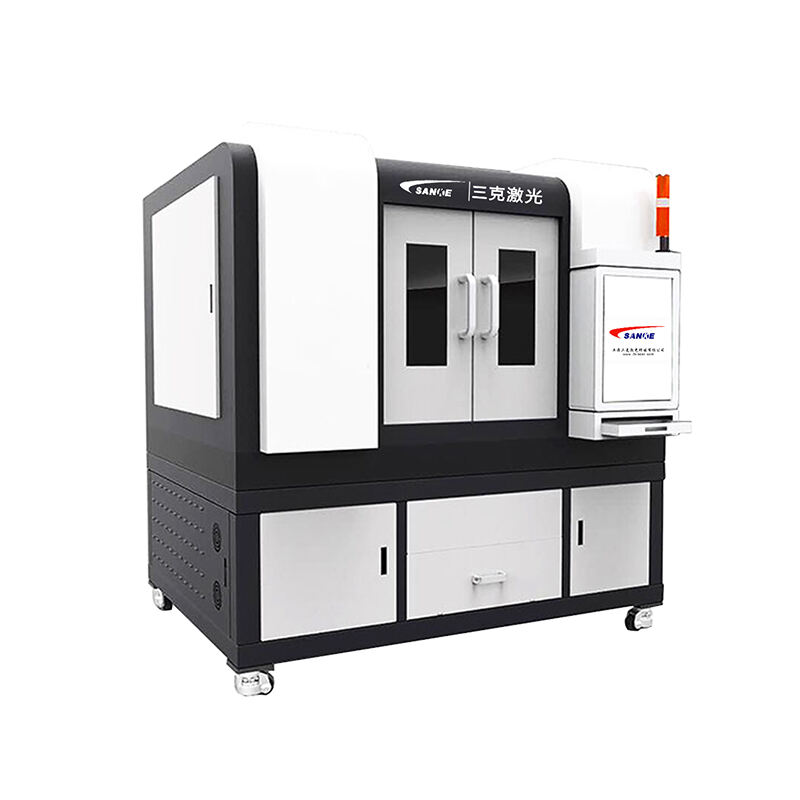

The exceptional material processing versatility of laser cutting machines for metals enables manufacturers across diverse industries to consolidate multiple cutting operations into a single, highly efficient system. This comprehensive capability spans ferrous materials including carbon steel, stainless steel, and tool steels, as well as non-ferrous options such as aluminum, brass, copper, titanium, and specialized alloys used in aerospace applications. The laser cutting machine for metals demonstrates remarkable adaptability in processing material thicknesses ranging from delicate foils measuring mere fractions of millimeters to structural plates exceeding 50 millimeters in thickness. Each material type requires specific parameter optimization, and modern systems automatically adjust laser power, cutting speed, assist gas selection, and focus position based on programmed material specifications. The thermal management capabilities ensure minimal heat-affected zones regardless of material thermal conductivity, preserving the metallurgical properties essential for structural applications. Specialized cutting techniques enable processing of pre-coated materials, perforated sheets, and composite metal structures without compromising surface finishes or structural integrity. The laser cutting machine for metals excels in creating complex three-dimensional components through advanced beveling capabilities, producing chamfered edges and angled cuts that eliminate secondary machining operations. Multi-layer cutting functionality allows simultaneous processing of stacked materials, significantly increasing productivity for high-volume applications requiring identical components. The system maintains consistent edge quality across varying material compositions, eliminating the need for different tooling sets or extensive machine reconfiguration between job changes. Micro-perforation capabilities enable the creation of precise hole patterns for filtration, ventilation, and decorative applications with hole diameters as small as the material thickness allows. The laser cutting machine for metals processes exotic materials used in medical device manufacturing, including biocompatible titanium alloys and specialty stainless steel grades that require contamination-free cutting environments. Surface treatment compatibility ensures that pre-painted, galvanized, or powder-coated materials can be processed without compromising protective finishes beyond the immediate cutting zone. The versatility extends to processing materials with varying surface conditions, from mill-finish plates to polished sheets, maintaining consistent cutting quality regardless of initial surface characteristics.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES