IntelliWELD II FT3D flying scanning galvanometer

3K New developed 3D flying scanning galvanometer laser welding system.

Mainly used for new energy battery laser welding, semiconductor parts laser welding, etc.

At present,mainly for the domestic large-scale lithium battery factory equipped with the welding system.

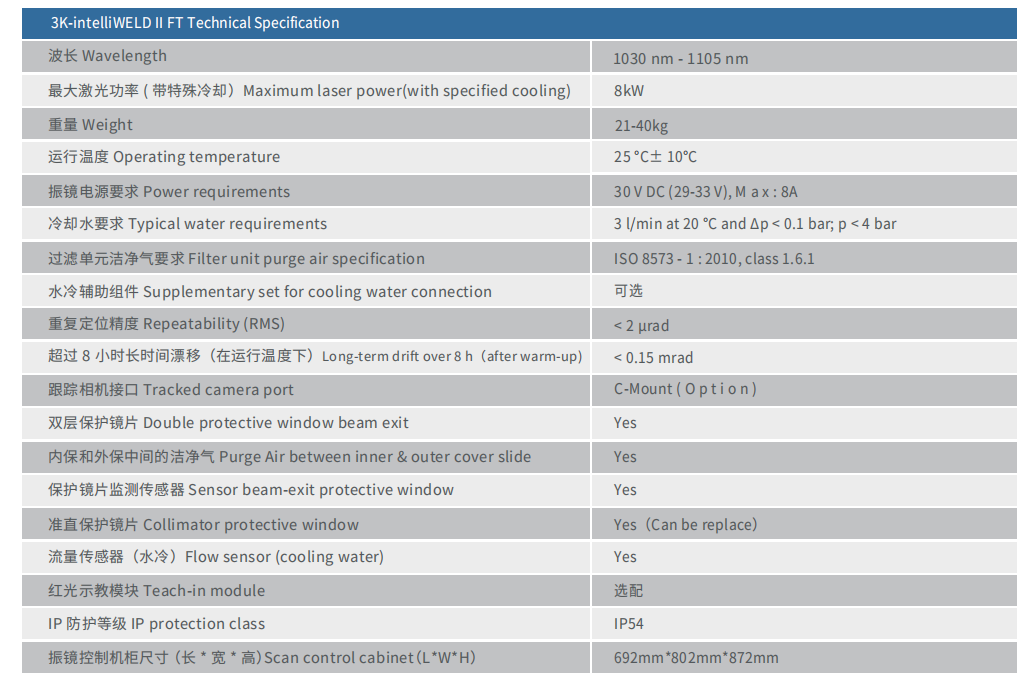

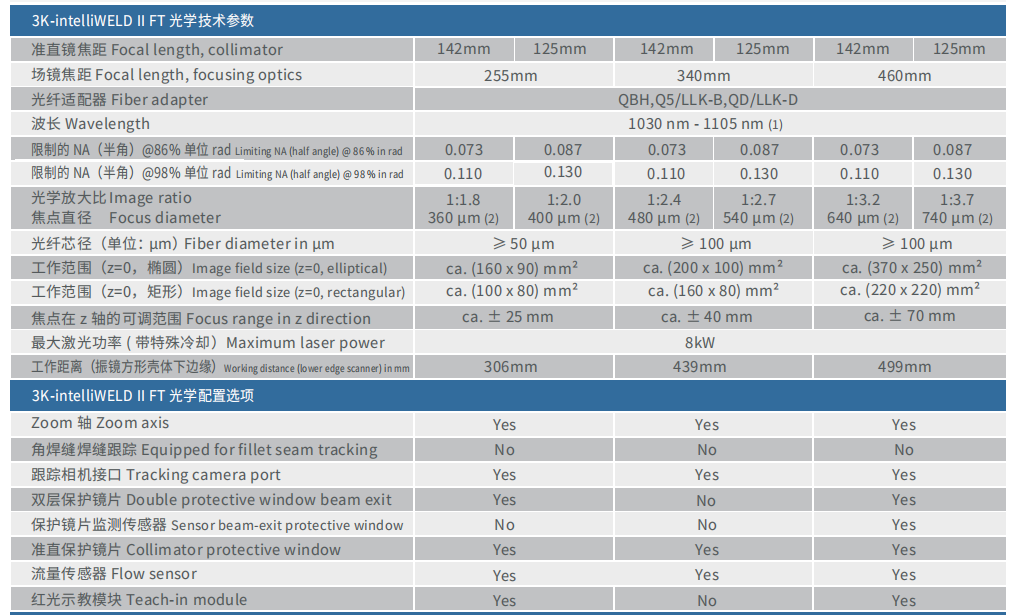

This welding system with German Scanlab intelliWELD 3D scanning galvanometer for different areas of welding Applications. The optics are suitable for laser sources up to 8kW.

The intelliWELD 3D scanners can be used with laser sources of up to 8kW, either disc or fiber. The intelliWELD 3D scanning galvanometer can be mounted directly on the industrial robot via a flange.

The intelliWELD 3D scanning mirrors can be flange-mounted directly onto industrial robots, linear axis systems or small machining systems.

The intelliWELD 3D scanner can be flange-mounted directly onto industrial robots, linear axis systems or small machining systems, and guides the positioning laser efficiently and rapidly along a simply programmable predefined path.

The latest intelliWELD 3D scanners can be mounted directly on industrial robots, linear axis systems or small machining systems via a flange. The latest intelliWELD IIFT 3D includes an integrated focusing system (especially for the case of overlay welding, where the variable focus size allows for flexible adjustment of the weld seam width).

The latest intelliWELD IIFT 3D includes an integrated zoom system (particularly suitable for stack welding cases, where the variable focus size enables flexible adjustment of the weld seam width).

When combined with the RTC5 control board, the intelliWELD 3D galvanometer system is capable of the IntelliWELD 3D oscilloscope system, when combined with the RTC5 control board, enables SCANLAB's fully digital iDRIVE technology.

The RTC5 control board integrates a safe design and additional expansion features to provide a complete solution for laser and process safety. iDRIVE technology is capable of providing a complete solution for laser and process safety.

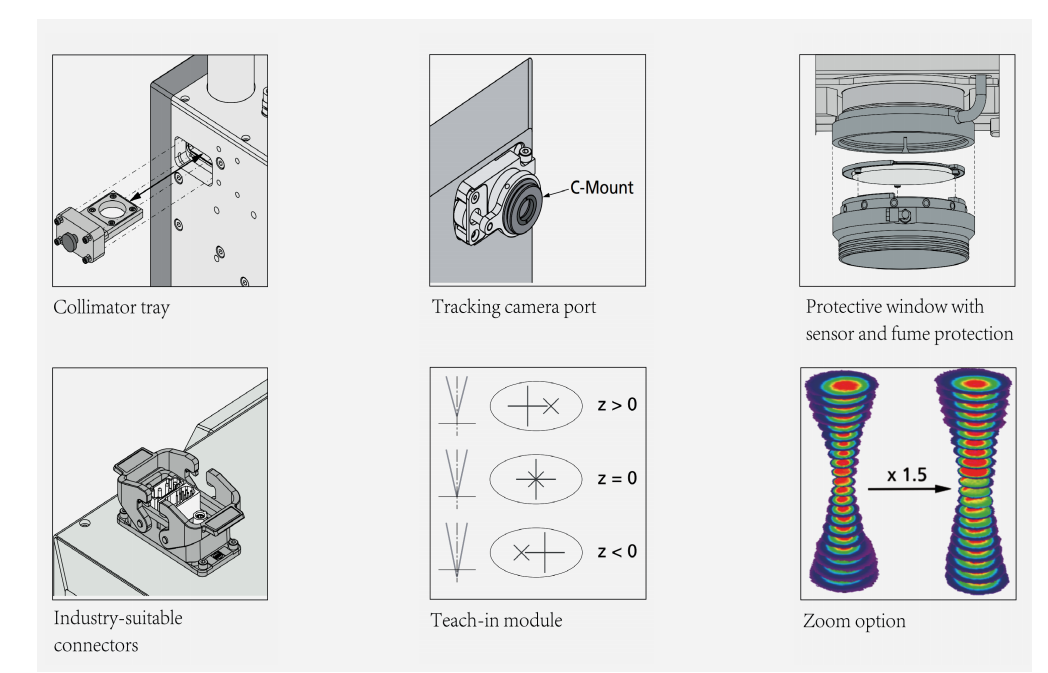

The iDRIVE technology enables real-time monitoring and control of all critical parameters of the galvanometer system, such as replaceable protection.

The iDRIVE technology enables real-time monitoring of all critical parameters of the galvanometer system, such as the temperature of the replaceable protective mirrors or the collimating inlet.

The galvanometer control system (robot synchronization system) perfectly supports the intelliWELD 3D and robot linkage functions.

3D and robot synchronization. The complete laser system (robot, laser source, intelliWELD 3D) can be centrally controlled.(robot, laser source, intelliWELD and other peripherals).

The integrated interlocking signals allow the galvanometer system to be controlled independently of the robot.

The integrated interlocking signals allow the galvanometer system to be integrated into the safety loop independently of the software. Simplicity

The simple application of the system makes the entire welding process more efficient and easier.

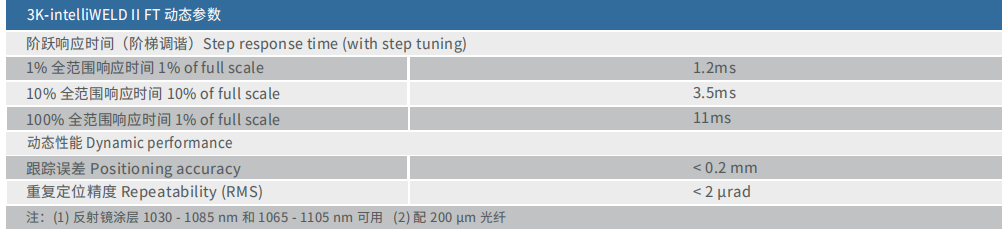

The intelliWELD 3D galvanometer system avoids time-consuming repetitive positioning of the motion device's attitude and trajectory.

trajectory of the motion device and the time wasted in repetitive positioning, the intelliWELD 3D mirror system speeds up the overall welding process considerably and reduces the time between weld seams and reduces the time it takes to travel between weld seams to the millisecond level. Laser utilization rate is greatly improved, leading to increased productivity.

<Video width="50%" height="25%" style="display: block; margin-left: auto; margin-right: auto;" controls="controls">