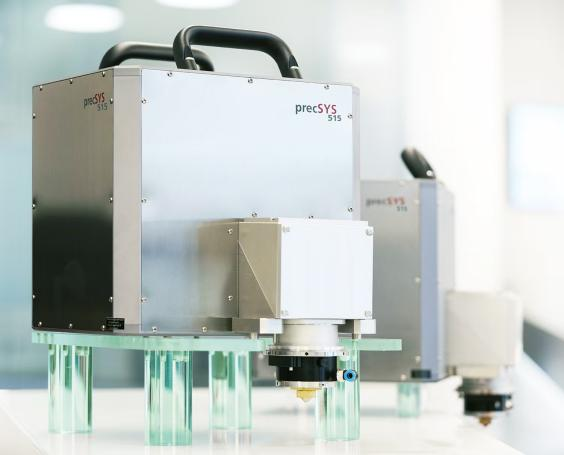

Our company purchased a new original 5-axis micromachining laser galvanometer system, which has been used in less than two sets in the Chinese market. The product is a new high-precision galvanometer system that needs to be customized in Germany. The processing precision is very high, mainly used for laser drilling.

About PrecSYS 5-Axis Micromachining System

The precSYS micromachining sub system enables laser micro processing and drilling of flexible geometries including laser cutting and structuring. Designed for ultra-short-pulse (USP) lasers, precSYS enables exceptionally clean processing of variable holes and structures without post-processing.

The precSYS combines leading-edge high-end scan technology, integrated control, embedded PC and user-friendly software. This enables laser micro processing with ultimate dynamic performance and precision.

The DrillControl software with graphical user interface (GUI) facilitates straightforward creation, simulation and testing of microprocessing jobs.

The very robustly constructed scan system is optimized for industrial usage. It's compact, modular design with specially adapted hardware and software interfaces allows easy integration into customer-specific laser machines and automated IoT (internet of things) environments.

The system is available for UKP lasers with wavelengths of 1030 nm, 1064 nm and 515 nm.

• Flexible USP laser processing with variable angle of incidence (positive and negative)

• Speed-independent contour fidelity

• Industrial proven and highly-integrated modular design with embedded PC

• Automatic fine adjustment module for long-term accuracy

• Intuitive DrillControl software with GUI to easily create and simulate processing jobs

• Ultra-precise pre-calibration

• Comprehensive on-site customer service and training